Let us know what type of content you'd like to see more of. Fill out our three question survey.

How Can the Mexican Automotive Industry Capitalize on Data-Driven Global Value Chains?

May 25, 2022

Smart factories could position Mexico as an Industry 4.0 hub and open doors to data-driven global value chains (GVCs).

Mexico is embracing Industry 4.0. The digital factory in Puebla, the aerospace corridors in Querétaro, Guanajuato, Baja California, Sonora, Chihuahua, and Nuevo León showcase Industry 4.0 manufacturing throughout the country. Smart factories are facilities that primarily use automated tools and machines, from production robots to transportation devices or 3D printers. Products are equipped with sensors that allow them to connect and exchange data and communicate with each other. They make up a cyber-physical production system (CPPS) connected via the industrial Internet of Things (IoT).

Data are the smart factory’s blood vessels and the key enabler of modern global value chains (GVCs). In the networked smart factory, identities can be assigned to tools, machines, products, and materials. Items at each level of the GVC can thereby be precisely located and tracked. This networked and automated production environment is supplemented with “big data” (huge amounts of data from millions of nodes within a network, including the ability to process and analyze large amounts of data using cloud computing, artificial intelligence (AI), and machine learning). Data can be handled, processed, and analyzed in real time and passed on through GVCs. Greater customization is possible while retaining speed and efficiency. Individual products are networked and identifiable; customization is possible by drawing on user data, while customer data is directly transferred to machine data. Cloud computing and additive manufacturing enable decentralized production.

Digital Transformation and Datafication

Data is no longer centrally stored but located in data lakes that can be accessed from anywhere in the world. Since decision-making based on data can be decentralized, manufacturing in data-driven GVCs can consist of multiple, flexible, and localized systems and machines with functions that are distributed throughout a network without a compact hierarchy. Connecting equipment, machines, sensors, and systems horizontally and vertically across GVCs provides valuable data insights. Digital transformation and datafication facilitate quick data exchange between manufacturing assets and are gathered at a central control center for analysis. Effective data analytics, data transfer, and data-sharing mechanisms are essential for unlocking meaningful data.

Photo credit: McKinsey.

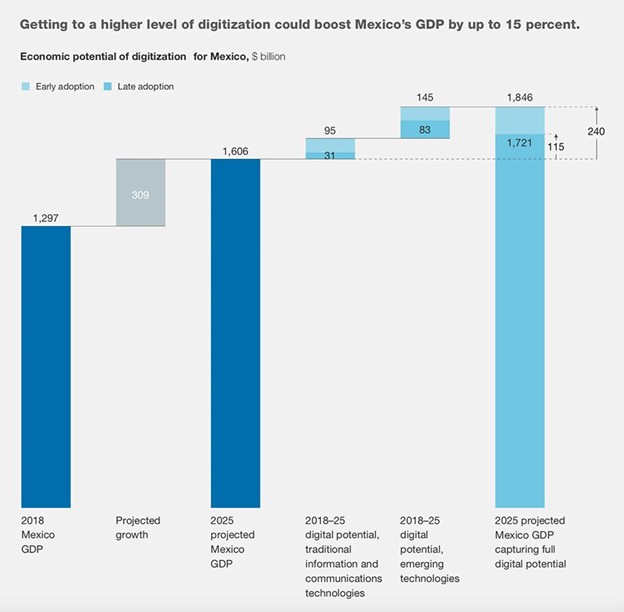

The McKinsey Global Institute estimates that if Mexico were to attain a “good” or “very good” digital maturity and datafication rating, the country’s gross domestic product (GDP) would increase by between 7 percent to 15 percent (or $115 billion to $240 billion) by 2025. This growth would come from greater productivity and employment in existing sectors, the creation of new digital (or digitally powered) businesses, the expansion of the digital sector, and successful labor force transition to these new digital industries. Smart factories could position Mexico as an Industry 4.0 hub and open doors to data-driven GVCs. The Mexican automotive industry is poised to benefit the most from digital transformation and datafication.

Yet much remains to be done. Many Mexican manufacturers still have legacy systems that support production with data silos or cumbersome processes that are only partially digitized. These legacy systems contribute to delays, outdated information, and decreased productivity. Changes need to be introduced if Mexican manufacturers are to remain competitive in data-driven GVCs. Industry 4.0 efforts require integration of cutting-edge international networks, successful technology transfers, intellectual property commercialization, talent management and modern data environments, and data governance systems. While the automotive and aerospace industries in the northern part of the country are moving from Industry 3.0 to Industry 4.0, this is not the case for industries in the southern and southeastern parts of the country, which continue to face many challenges in terms of industrial development. Looming questions that remain to be resolved in this regard are Mexico’s persistent and growing structural problems, including low labor productivity, poverty, and inequality, which will affect the inclusive and equitable impact of Industry 4.0 on Mexican society.

Automotive Industry Could Benefit Most

Mexico’s automotive industry could benefit from digital transformation and the introduction of digital threads and digital twins. In 2020, the share of Mexico’s automotive industry in total manufactured exports was 41.6 percent ($139.8 billion), higher than that of any other industrial sector. Car, trucks, and automotive parts are key components of Mexico’s manufacturing sector and account for a large share of employment and exports. There are several automotive original equipment manufacturers (OEMs) in Mexico, such as BMW, Chrysler, Ford, General Motors, Honda, Kia, Mazda, Nissan, Toyota, Mercedes-Benz, JAC Motors, Volvo, Volkswagen, and several other smaller brands. These companies have built 20 plants in Mexico that depend on a robust supplier presence to enable a smooth operation. The two key clusters are in Saltillo, Coahuila (“the Detroit of Mexico”) and a corridor along the Coast of Bajio; other clusters are developing elsewhere (for example, in Puebla, which now has a sizeable automotive industry in an otherwise mostly low-wage and unsophisticated production environment).

Mexican automakers have already started introducing digital twins in their operations. Automakers use digital twins for a digital representation of the ongoing production process by adding sensors along the many stages of the production process to monitor operations and have a digital representation of each of the transformations’ analog steps (pressing, assembly). Data are then processed and analyzed to optimize production flows, input consumption, labor utilization, maintenance planning, and more. In the automotive industry, digital twins can either be a virtual version of a tire or passenger vehicle, the methods for how these items are built, or the entire production line. They can even be an entire factory, a network of plants, or the end-to-end supply chain. Mechatronics, electronics, system-on-chip, and embedded software are designed and simulated in the virtual environment. Digital technologies and datafication could provide the necessary flexibility to optimize the automotive industry’s production process without relying solely on labor flexibility, which has been the main source of adjustment in Mexico. Datafication can provide for better quality control, cost reductions, product improvement, and a better flow of data across the GVC, thereby improving product quality and enhancing process and product innovation.

Despite all of these achievements, Mexican firms report that the benefits of digital transformation are still not able to rival low labor costs. However, labor flexibility will no longer suffice in the long run since the current organization of production calls for flexibility and control over all inputs to meet prompt delivery requirements and to reduce costs. Better inventory management based on timely data can lower costs. Flexibility is mandated by the just-in-time, lean production organization of the entire vertical chain, which must respond in real time to data provided by dealers in the car market. Within this configuration, the burden of adjustment is moved down the GVC from OEMs to Tier 1 suppliers, and from these to their Tier 2 and Tier 3 suppliers.

The datafication and digital transformation of Mexico’s automotive industry are prerequisites for keeping up with global competitors and fostering the industry’s strategic importance for the country, given its size and impact. Automotive firms and Tier 1 suppliers in Mexico have already elaborated a digital transformation strategy at the head offices which is being implemented by subsidiaries. Moreover, there is no difference in digital transformation levels between firms that produce mid-range cars and those that manufacture high-end vehicles.

However, the dependence of Mexico’s automotive industry on the strategic decisions of international players represents a vulnerability amidst the rapid changes triggered by digital transformation, smart manufacturing, and the datafication of automotive GVCs. As regions and players outside the traditional automotive industry gain momentum and technological and market trends such as electric vehicles redefine mobility, the core competencies for success are quickly changing. Electronics and software account for a considerable share of a vehicle’s value. Changes in production processes require skills that have thus far not been included among the core competencies of automotive engineering. The increased relevance of (big) data and digital devices could shift the power from OEMs and suppliers to high-tech and digital players. How this plays out might affect GVCs and Mexico’s role in them. The rise of new competitors from emerging economies and would-be entrants from other sectors competing to master the latest digital and software technologies threaten the industry’s established structure. Survival will require adjustment to these new trends, which in turn hinges on local capabilities (public and private) to adapt and provide high value-added goods and services to data-intensive GVCs.

Data-Driven GVCs Will Rest on Policies that Harness the Power of Data

Data-handling capabilities will be crucial in the new environment. Data are the blood vessels of the digital economy and have increasingly become instrumental in gaining access to GVCs. The establishment and implementation of secure data-sharing mechanisms and cross-border data transfers could open up several opportunities, such as increased national GDP and private sector productivity through digital and integrated supply chain systems, the introduction of smart factories, breaking down data silos in manufacturing, and unlocking access to meaningful data. This could also, however, exacerbate gaps between winners and losers in the new production landscape.

To fully realize the commercial and social benefits of data generated across the automotive industry, industry participants need a secure and robust data market where they can come together to trade data. This market will enable organizations to implement more efficient data collection processes, support their business objectives, and engage in transactions in the data marketplace. Globally, data exchanges are expected to create $36 billion in operating profits for OEMs from jointly run data exchanges operated at scale, with benefits primarily derived from third-party monetization and reduced cost of data acquisition for OEMs. OEMs (Tier 1) in Mexico are best placed to accelerate the transition toward data-driven GVCs. This will likely necessitate private investment to create knowledge and develop the workforce’s capacity, public policies, and incentives to accelerate public-private partnerships. One noteworthy initiative in this regard is Industrial Transformation Mexico.

Adequate data governance policies and regulations are needed to achieve successful integration of Industry 4.0 practices and data-driven GVCs in the Mexican economy. National regulations that impose excessive data-transfer requirements or local data storage conditions can influence the structure of automotive GVCs and their ability to navigate through datafication and digital transformation. The Government of Mexico has embedded the relevance of data for digital transformation in the National Digital Strategy (2013). Substantial efforts have been made to build the institutional, social, and economic infrastructure around digital transformation to support it. Mexico has also maintained a healthy interest in data-processing technologies, such as AI, which will upend industries. The U.K. Embassy in Mexico, with support from the Office of the Mexican President, commissioned Oxford Insights to draft a national AI strategy for the Government of Mexico. In June 2018, their findings and recommendations for the National Artificial Intelligence Strategy Mexico were published. The Government of Mexico has also supported the creation of ia2030, a multi-sectoral partnership to set the course for AI development in the country.

Originally published on the UNIDO Industrial Analytics Platform

This piece is based on the 2021 IDB report on data in value chains.